Building energy consumption accounts for approximately one-third of total social energy use. In China, the energy demand from buildings has been rising steadily since the late 1970s, when it made up about 10% of the national total. Today, this share has climbed to 27.45%, and with continued urbanization and improved living standards, it is expected to reach around 35% in the future. In developed countries, building energy use typically makes up about 33% of the national total. Given this trend, the Ministry of Construction's research highlights that building energy use has become a critical challenge for China’s economic development. Currently, a large proportion of buildings in China are high-energy consumers. As of the end of 2002, only 230 million square meters of buildings were considered energy-efficient, while over 40 billion square meters of existing structures are classified as high-energy buildings. This massive scale contributes significantly to the energy crisis. According to officials from the Ministry of Construction, by the year 2000, the construction sector consumed 376 million tons of standard coal annually, representing 27.6% of the country's total energy use. Additionally, building energy use contributes nearly 25% to the nation's greenhouse gas emissions. The heating system alone consumes 18 million tons of standard coal per year, causing an estimated 7 billion yuan in economic losses and emitting 520,000 tons of carbon dioxide. If this trend continues, by 2020, building energy consumption could reach 108.9 billion tons, and summer air conditioning peak load would be equivalent to the full capacity of three Three Gorges Dams. With annual construction reaching 1.6 to 2 billion square meters—more than all developed countries combined—and over 97% of these being high-energy buildings, the situation is worsening rapidly. Without immediate action on energy-efficient design, the energy crisis will only intensify. China's building energy efficiency lags far behind that of developed nations. After the 1970s energy crisis, many developed countries began investing in energy-saving technologies, but China was slow to respond. Today, the thermal performance of building envelopes in heating areas in China is much worse compared to similar climates abroad. For instance, the heat transfer coefficient of exterior walls is 3.5 to 4.5 times higher, windows have 2 to 3 times more heat loss, roofs show 3 to 6 times more heat transfer, and doors and windows are 3 to 6 times more air-leaky. In Europe, average annual heating energy use is about 6 liters of oil per square meter, equivalent to 8.57 kilograms of standard coal. In contrast, Chinese buildings consume 50% more energy, with heating needs reaching 12.5 kilograms of standard coal per square meter—about 1.5 times that of European countries. In Germany, which has a climate similar to Beijing, the heating standard before 1984 was comparable to Beijing’s. However, by 2001, Germany had reduced its average heating energy use to just 3.7 to 8.6 kilograms of standard coal per square meter—about one-third of what it was previously—while Beijing still uses 22.45 kilograms per square meter. These gaps highlight the urgent need for improvement in China's building energy policies and practices. Toroidal Conductivity Sensor, also called toroidal conductivity probe, is an electromagnetic induction device used to measure the conductivity in water. This article explores the toroidal geometry's significance, conductivity measurement principles, and the distinct advantages of Daruifuno's toroidal sensor design in industrial applications. We will examine core concepts, operational principles, and practical applications while highlighting how this technology enhances accuracy in challenging environments. The toroidal configuration refers to the sensor's ring-shaped structure, which creates a closed magnetic circuit. This design enhances electromagnetic efficiency by concentrating magnetic flux within the conductive medium. Unlike conventional coil designs, the toroidal geometry ensures uniform magnetic field distribution, minimizing edge effects and improving signal-to-noise ratio. The closed-loop architecture also enables effective shielding from external electromagnetic interference, making it ideal for industrial settings with complex electromagnetic environments.  Conductivity is also commonly called Electrical Conductivity, which refers to the ability of a substance to conduct current. It is expressed as the amount of current that can pass through per unit voltage, and is also measured in "mhos" (now renamed Siemens). Conductivity in water indicates the ability of water to conduct current. Conductivity is related to the total ion concentration, mobility, valence, relative concentration, and water temperature in the water. Generally, the higher the conductivity, the more electrolytes there are in the water. Since most salts can be ionized, conductivity can also indicate the amount of total dissolved solids in the water. The conductivity of pure water is not very good, but when there are electrolytes and ions in the water, its conductivity will increase significantly, and the higher the ion concentration in the water, the higher the conductivity. Therefore, the higher the salinity of seawater, the higher the conductivity. Conversely, as long as you know the conductivity of the seawater at that time, you can infer the possible salinity at that time. Monitoring conductivity is essential for: Traditional conductivity sensors using parallel-plate or concentric-ring designs suffer from susceptibility to polarization effects and electrode fouling. Daruifuno's toroidal design overcomes these limitations through: Daruifuno's toroidal conductivity sensors deliver unmatched performance in critical applications: For comprehensive conductivity monitoring solutions, explore Daruifuno's full range of industrial conductivity sensors. Our experts provide customized solutions for OEM integration and process optimization. Contact us today to upgrade your conductivity measurement capabilities with cutting-edge toroidal technology. View All Conductivity Sensors → Toroidal Conductivity Sensor,Toroidal Conductivity Probe Suzhou Delfino Environmental Technology Co., Ltd. , https://www.daruifuno.comOverview

The Significance of Toroidal

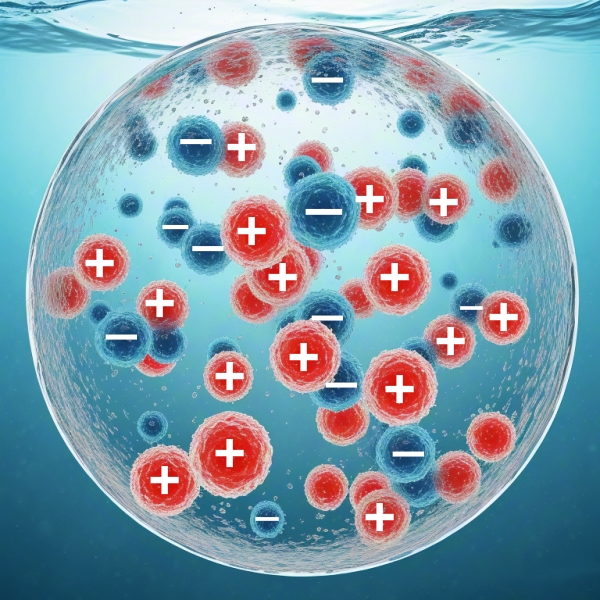

Understanding Electrical Conductivity Measurement

Advantages of Toroidal Conductivity Sensors

Why Choose Daruifuno's Toroidal Sensors?

Â

Â

Â