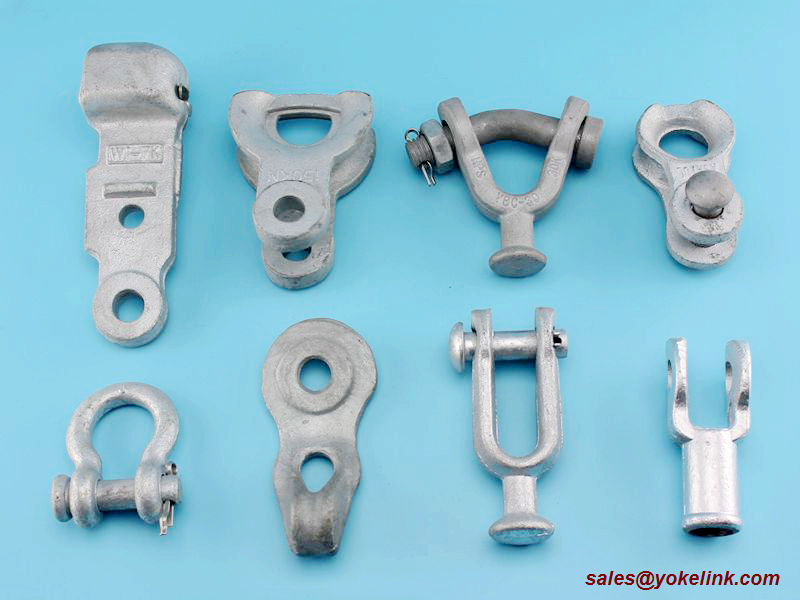

Transmission hardware fittings are components used in the construction and maintenance of transmission lines for electricity or telecommunications. These fittings are designed to connect, support, and secure the different parts of the transmission line, ensuring proper functioning and reliability. Yokelink supply a full line of Tower hardwares, , provide part number to get a quote on these products, leave your message, or send us an email to get answers for your questions or product you needed. Socket Eyes are used for connecting conductor clamping devices to ball and socket type insulators. Made by malleable iron, hot dip galvanized to meet ASTM A153 specification. Ball Eyes are used to attach ball and socket insulators to other associated hardware. Hot dip galvanized to meet ASTM A153 specification. Thimble Cleivs are used for attaching guy to pole eye plate. Hot dip galvanized to meet ASTM A153 specification. Turnbuckles are used as adjustable extension links to maintain proper tower clearance on assemblies at tower end. Strain Clamp used for distribution and transmission line construction with all aluminum ACSR, or aluminum alloy conductor. Transmission Hardware Fitting, Socket,Ball eye, Hot line, Chain Link, Turnbuckle, Suspension, Strain, Yoke plate,malleable iron,hardware,tower,links Ningbo Yokelink Machinery Co.,Limited , https://www.yokelink.com

Some common types of transmission hardware fittings include:

Suspension Clamps: Used to hang the conductors from the transmission towers, providing support and preventing sagging.

Dead-end Clamps: Used to terminate the conductors at the ends of the transmission line, providing support and preventing them from slipping.

Splice Sleeves: Used to join two conductors together, ensuring a secure and conductive connection.

Insulators: Used to electrically isolate the conductors from the transmission towers, preventing electrical leakage and ensuring proper insulation.

Guy Wire Fittings: Used to secure and stabilize the transmission towers, preventing them from swaying or collapsing.

Connectors: Used to connect different components of the transmission line, such as conductors, insulators, and fittings, ensuring a secure and reliable connection.

On the morning of March 18, 2013, Liu Jinchang, the General Manager of China Superhard Materials Network, and Shi Chao, the Executive Deputy General Manager, made a visit to Jiaozuo Huajing Diamond Co., Ltd. in Henan Province. The company, formerly known as Jiaozuo Meijing Technology Co., Ltd., was warmly received by Dr. Chuan Chuanyi, the Chief Engineer, and Chen Xiaozhou, the Production Minister. Founded in 2009, Jiaozuo Huajing Diamond Co., Ltd. is a specialized enterprise focused on the production of synthetic diamond large single crystals using advanced technology developed by Dr. Qi Chuanyi. This innovation filled a critical gap in the industrial-scale production of artificial large single crystal diamonds in China.

During the meeting, discussions covered the development of large-scale synthetic diamonds both domestically and internationally, along with an analysis of the current market situation. Dr. Chuan Chuanyi provided a detailed overview of the company's development plans and ongoing projects related to the production of large single crystal diamonds. Under the leadership of Dr. Qi Chuanyi, the team toured the new plant area currently under construction, which spans 120 mu. They also witnessed the foundation work for the new facility.

The company is equipped with dozens of six-face top presses, and its monthly production capacity reaches 15,000 units. The size range of the sheet-like single crystals produced varies from 3×3mm to 8×8mm, and sales have been consistently strong. In addition, they produce gem-quality single crystals, showcasing the company’s commitment to innovation and high-end product development.

In the afternoon, the delegation visited Jiaozuo Zhengheng Industrial Co., Ltd., where they were welcomed by Chairman Zheng Zhi and Deputy General Manager Zhao Yanbing. Zhengheng Industrial is a professional manufacturer of metal powders, utilizing gas atomization and water atomization technologies to produce pre-alloyed powder and synthetic diamond catalyst powder. The two sides exchanged insights on the current market trends for catalyst alloy powders.

Chairman Zheng Zhi emphasized that this year marks a crucial phase for the company's growth. He noted that domestic manufacturing technology for alloy catalyst powders still lags behind global standards, and a significant portion of high-grade diamond production relies on imported catalysts, increasing overall costs. In Henan Province, only Zhengheng Industrial is actively working on developing catalyst alloy powder technology, making it a key player in the region.

Chairman Zheng highlighted the importance of R&D in catalyst alloy powder, stating that it is vital for the company's long-term sustainable development. During the visit, General Manager Liu Jinchang had a cordial conversation with Chairman Zheng Zhi, exchanging valuable perspectives on industry challenges and future opportunities.